How RFID Applicability Turns-up Supply Chain Mgt. and Logistics

Gliding ahead with precision and care, RFID Technology have solved issues in Supply Chain Management and Logistics with utmost flair!

When you head towards your favorite car dealer in search of a new car, you are pretty aware of what your family needs but if you happen to lock in onto a sports car that goes beyond your estimated budget and does not capacitates well, that feels reckless! It clearly depicts a scenario that accord to organizations in search of a solution for tracking assets.

Radio frequency identification (RFID) has revolutionized the asset tracking practice for many such companies (including large retail outlets), where RFID tags are compulsorily attached with every object on the shelf. These are implemented to take care of incidences of theft and removed only once customers complete the payment process. RFID process offers a quicker way to track multiple items over extended distances. Although it seems to fit the needs of most of the organizations out there, for others, it might be just next expensive sports car that does not necessarily meet the expectations and most basic needs.

RFID is slightly slow in the performance that keeps it away from overtaking the barcode, which is in implementation as a reliable and cost-effective solution. The combination of the two can really work as a confident solution for asset tracking, but RFID technology alone suffers from a few challenges, discussed below:

- RFID can be expensive to implement.

- The technology underlying RFID can be a challenge for engineers.

- There can be collisions between RFID Reader and RFID Tags. There can be interference in the signal and abundance of tags at one time can often confuse the reader.

- RFID tags can often be difficult to read in case of metals and liquids as the signal bounces all over the place. Signals can often get absorbed in the process.

What is RFID?

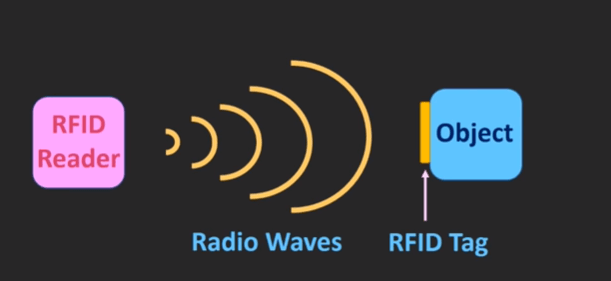

Radio-frequency identification (RFID) is a wireless system to send and receive signals via radio-frequency electromagnetic fields. To start with, RFID tags can be attached to the objects (that are placed on a shelf within a shopping mall) for the purposes of automatic identification and tracking of goods. RFID technology uses are especially beneficial in supply chain management and can be used for various aspects like inventory management, warehouse management, freight transportation, and retailing and manufacturing and also help them achieve high performance and tracking.

Objects can be books in the library, any item you’re purchasing from the shopping mall, any inventory in a warehouse or it could be your own car. It can as well be used to track animals and birds.

An RFID tag is attached to the object that is to be tracked. If the object is in the range of a reader, then this RFID tag is used to transmit its feedback signal to the reader. It is very similar to the technology used in a barcode. In the case of barcode, the object and scanner should be in the line of sight. As opposed to this, in RFID technology, the object has to be within the range of the reader and is able to identify it and send feedback signal.

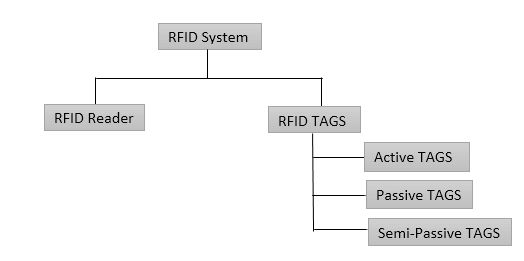

What is RFID System?

A basic RFID system consists of RFID reader and RFID tags. Latter can further be classified as Active Tags, Passive Tags, and Semi-Passive Tags.

Passive tags are compact and come in many forms: Can be of the size of a keychain, credit card or a label. These do not have their own power supply. So they rely on the radio waves coming from the RFID reader. Semi-Passive tags have their own power supply. But they rely on the signal coming from the RFID reader, in order to transmit back. Active tags come with their own power supply. Range of passive tags is less than that of active and semi-active tags, but they are the most prevalent ones.

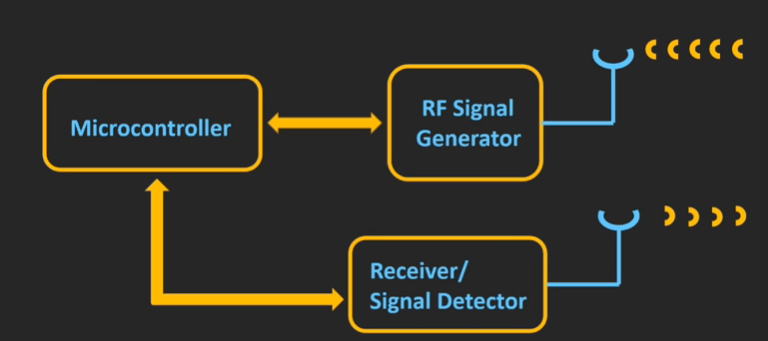

RFID Reader

RFID Readers come in many sizes and shapes. These can be a handheld reader or can be as large as the size of a door (which can normally be seen within shopping malls).

An RFID Reader mainly consists of 3 components:

- A Signal Generator (Generates a radio wave which is transmitted through this antennae.)

- Microcontroller

- Receiver/Signal Detector (RFID tag receives the signal and processes the information being sent by the RFID tag)

An RFID Tag

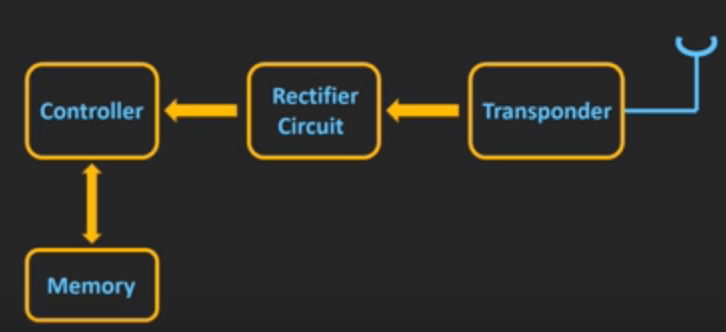

The first component that can be seen inside an RFID Tag is a transponder – coming from the reader and sends the signal back to the reader. The energy coming from the rectifier circuit is stored inside the capacitor. This energy is used for the controller as well as the memory element.

Working Principle of RFID System

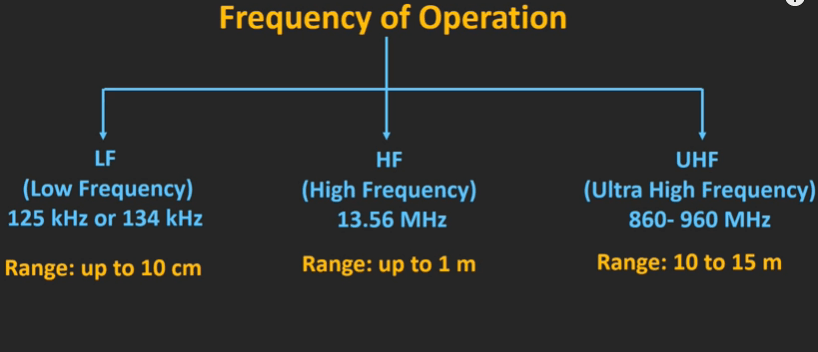

The RFID system is dependent upon its frequency of operation.

In case of low frequency and high-frequency RFID Tags, it is based on inductive or near field coupling. While in case of ultra-high frequency RFID Tags, it is based on an electromagnetic or far-field coupling.

RFID reader solves three purposes: It induces enough power into the tag, synchronizes the clock to tag, and acts as a carrier for returning data from the tag.

RFID working principle is based on inductive coupling. So the field which is being generated by RFID reader is to get coupled with antennae of RFID tag. This induces a voltage across the coil of the RFID tag. Some portion of this voltage gets rectified as a power supply for the controller as well as the memory elements. As RFID reader sends the radio waves of a particular frequency, a corresponding voltage is induced across the coil. This is also used to derive a synchronization clock for the controller. Now if we connect some load across the coil, it will start going across the load and if we change the impedance of this load, then the current that flows will also change. If we switch on and off the load, this will have a corresponding effect on the current. Switching of the load will affect current in equal proportion. This is known as load modulation. If this is done according to the data that is stored within the RFID tags then it can be read by RFID reader in the form of voltage. In this way, we are generating modulation within a carrier frequency.

In the case of ultra-high frequency RFID tags, the coupling between the RFID reader and tag will be far-field coupling. As RFID reader sends frequency, it gets a weak or backscattered signal from the tag in response. The intensity of this signal depends upon load matching across the coil. If the load is matched exactly then the intensity of the signal will be more and vice versa. If the condition of the load is changed according to the data, it will have a proportional effect on the signal that is being transmitted.

Benefits of RFID in Supply Chain and Logistics Management

Amongst the important ones are:

- Tracking assets in real-time: Tracking assets via RFID increases asset visibility. It helps in keeping track of the shipments and allows you to make decisions on the fly or facilitate changes by quickly re-routing the items.

- Improves Employee Productivity: It saves the time that is spent in manufacturing, quality check, shipping, tracking and securing the items. Plus the labor cost and cost of increased inventory add up to the overall overhead. If machines and technology reduce the human effort, it as well increases employee productivity.

- Reduces Accidental Losses: RFID process helps mitigate risks, any incidental theft, and loss due to ignorance or accident. Implementation of RFID helps ensure that all items and pallets are accounted for to mitigate costly risks, reduce misdistribution and loss and combat counterfeiting and theft. This often facilitates recalls. If possible these mistakes must be avoided as once occurred they take a lot of time and money to get fixed. Such accidental instances could result in lawsuits, heavy fines or even loss of a customer.

- RFID logistics ensures that there is full visibility, real-time information and the facility is much organized and productive.

Need To Cover Up Quickly

Supply Chain and Logistics have been increasingly making use of RFID in their processes to increase the visibility of transactions and manage their assets efficiently. While the barcode technology only allows tracking their inventory (that too within line of sight, when scanner and bar code are opposite), RFID technology even works to track the movement of their forklifts, trucks, returnable transit items or any other valuable assets that come in and out of their facility – in real time, even at a distance of few meters, so latter is more effective while tracking assets. Mobile app development agencies have begun to harness this technology for circulation and tracking of goods. Top app builder India has promoted this practice in sync with recent developments in logistics, supply chain, and retail markets.